Robotic machining company develops new technology to boost manufacturing productivity

Liverpool-based machining manufacturer CNC Robotics is helping manufacturers increase connectivity between digital and automated systems with its latest cloud-based software CNCR-Live.

CNC Robotics – the UK’s leading robotics integration company – worked with business support programme LCR 4.0 and partner Sensor City to design, collaborate and develop the potentially “market ready” cloud-based machine monitoring device.

The collaboration gave CNC Robotics access to specialised skills and engineering software such as the NI LabView Software Development System, which has enabled the company to combine digital and automated systems.

Integrating real-time diagnostic technology, CNCR-Live remotely monitors robotic data to predict when maintenance is needed. This prevents failures in the production process that can cause a slowdown or shutdown and as a result, boosts productivity.

Madina Barker, Director at CNC Robotics Ltd said: “Being able to utilise the specialist skills and resources at Sensor City has been a game-changer for us. It’s enabled us to develop our technology and given us the impetus to expand our team with the appointment of a new Systems and Applications Engineer.’”

“We are all very excited by the potential that the new CNCR-Live remote diagnostic technology will offer to the manufacturing industry.”

Simon Reid, Sector Manager for Advanced Manufacturing at the Liverpool City Region (LCR) Local Enterprise Partnership (LEP), added: “The LCR 4.0 project is geared up to help SMEs, like CNC Robotics, to create jobs and accelerate their product development by opening up access to the world-class knowledge assets that we have here in the region.

“This example shines a light on the power of collaboration in the region and the value that it adds to SMEs in real terms.”

The prototype is currently being tested and implemented in Sensor City’s engineering lab and CNC Robotics’ facility in Bootle, Liverpool.

Explore more

Women in LCR 4.0 Cluster Group

Identifying and Promoting the Opportunities of 4th Industrial Revolution for Women within Liverpool City Region.…

Business support programme assists almost 200 hi-tech firms

LCR 4.0, was proud to have helped almost 200 tech firms in the manufacturing space…

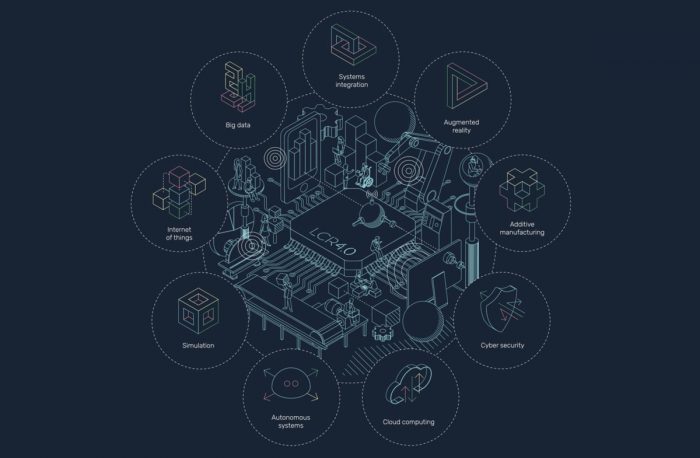

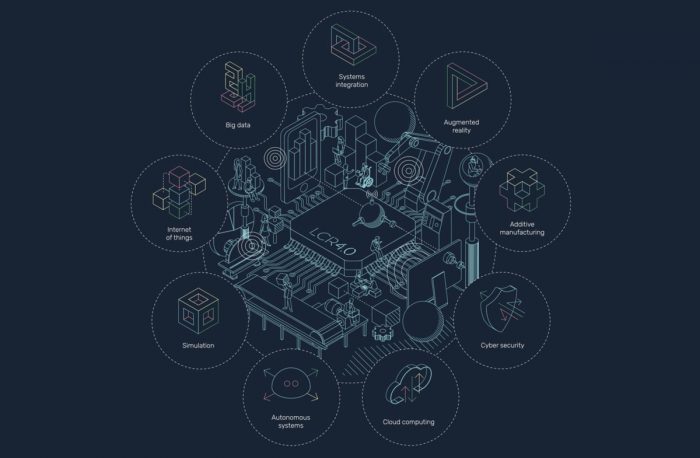

The Nine Pillars of Industry 4.0

You may have heard a lot about the fourth industrial revolution but do you know…