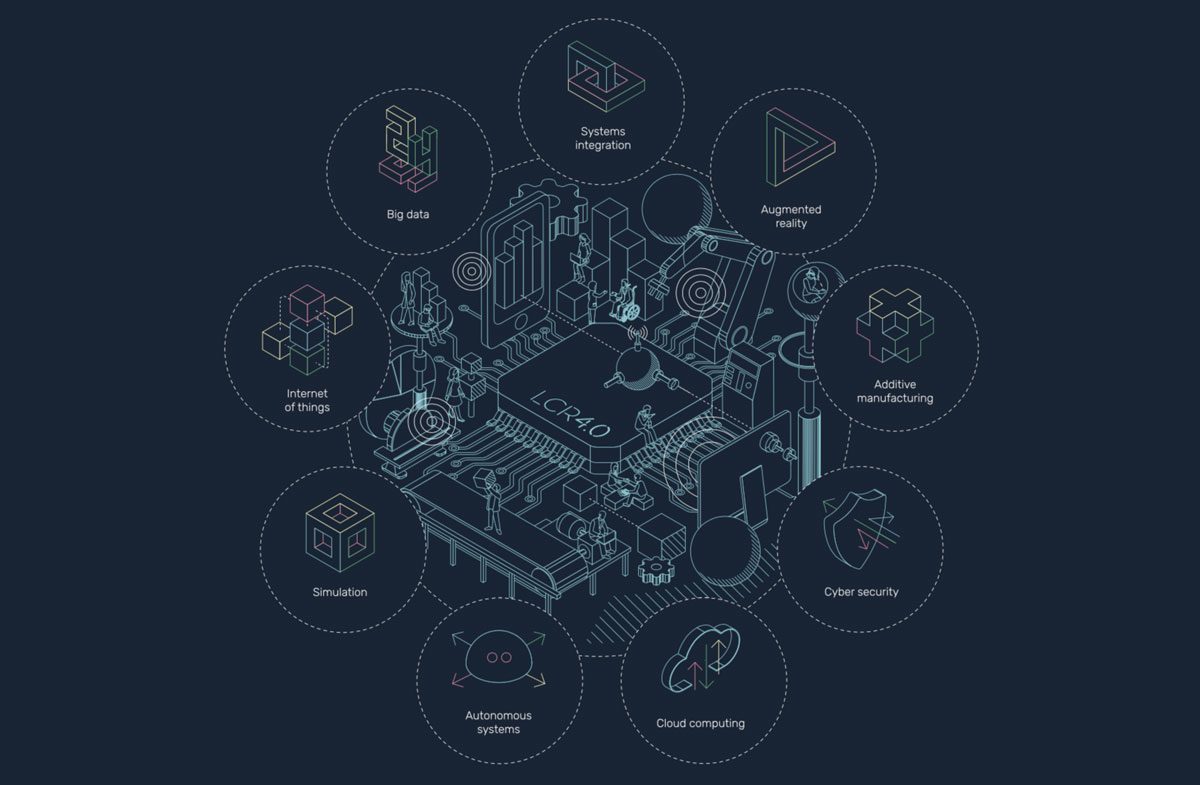

The Nine Pillars of Industry 4.0

You may have heard a lot about the fourth industrial revolution but do you know about the nine advancements in modern technology that form the foundation of Industry 4.0?

Read on below for details on the nine pillars that are helping to transform the operational potential of the manufacturing sector:

Big Data

Big data is now being collected by most companies but the issue remains with what these companies are doing with this. It is no good simply collecting data; companies need to use this for further actions and improved processes. LCR4.0 partners Sensor City and The Hartree Centre are able to help clients to turn this big data into useful insights which can then be converted into knowledge. This can be used to identify trends, patterns and relationships between inputs, processes and outputs, enabling improvements to be made across a number of manufacturing platforms.

Augmented Reality

Made popular and known worldwide via gaming and apps such as Pokémon Go, augmented reality allows for augmented imagery to be placed in front of the real-world. Other companies have introduced this technology to their businesses and apps such as IKEA, allowing customers to see furniture would look like in an existing room in their home using data based on size and colour.

Manufacturers could use this technology to showcase to customers what their products would look like without creating a physical copy. This way they are able to demonstrate what a product would look like or how it would work without the expense of a physical trial.

Key areas of industry relevant research are being developed by LJMU around using computer gaming and apps as a tool for industrial partners to use. LJMU also has active projects in 3D-simulation of logistics movement.

Simulation

This is a form of imitation of a situation, process or environment. Many companies all over the world within a vast range of industries are starting to utilise virtual realities within their own businesses including the medical sector.

LCR 4.0 project partner, the Virtual Engineering Centre (VEC) has collaborated alongside AlderHey Children’s Hospital to use real patient data to create a virtual heart – This allows for improved investigation, safer pre-op planning and the possibility of de-risking an operation before entering the operating theatre.

Manufacturers could utilise simulation for training purposes, showing workers the risk of working on a factory floor, without having to be in a dangerous physical environment; perfect for employee training and scenario planning.

Internet of Things

The Internet of Things involves connecting the internet to everyday items in order for them to send, receive and process data. This can lead to a decrease in production time, aid risk management and will save manufacturers valuable resources such as time and money.

Cloud Computing

This uses a network of remote servers to store, manage and process data. This can be very beneficial to manufacturing businesses who can bring their own intelligence and knowledge to all sales situations as well as introduce faster new product development processes, releasing new products to market in shorter time periods.

Cyber Security

While utilising the Internet of Things and cloud computing within your business can offer a number of benefits, these all need to be protected. Most manufacturers will want to protect their most valuable data including intellectual property, data on customers and their products.

LJMU has a dedicated cyber security research group, focusing on 4 key areas including: the security to safeguard systems against cyber-attacks, networking to support the systems’ distributed operations, game techniques to advance their user interaction and visualisation, as well as software engineering and artificial intelligence to build autonomic capability into the systems for intelligent operations.

Systems Integration

This technology allows for different computer systems to be linked together, enabling actual communication and the passing on of data between systems as software can act as a co-ordinated whole. This is ideal for all manufacturing companies as machinery from across the factory can be linked up together across the production line ensuring everything runs smoothly and efficiently.

Additive Manufacturing

Digital 3D design data is used to build a component in layers by depositing materials. Manufacturers of aeroplanes for example may consider using 3D printing for lighter parts which have not been filled with excess material. This can be beneficial as lighter parts make for a lighter plane, using less fuel but travelling at higher speeds.

Sensor City are experts in this field and can offer manufacturers the opportunity to use a 3D printer which prints on curves for microchips.

Autonomous Systems

Autonomous technology allows for machinery and robots, to act and behave autonomously after being programmed to do so. This technology allows for systems to think, act and react autonomously which also allows for decisions to be made remotely if control systems allow you to determine these behaviours from afar. This can all help contribute to a company’s competitiveness, productivity and of course, profitability.

Within the Engineering Technology Research Institute (ETRI) at LJMU, the Advanced Manufacturing Technology Research Laboratory is developing the next generation of high-value manufacturing systems for improved product quality and productivity at a reduced cost.

Explore more

Exciting Exercise In Growth: we catch up with Super North

This month, Dr Andy Levers, Technical Director at the Virtual Engineering Centre (VEC), caught up…

Beverston Engineering joins the Industry 4.0 race

Leading manufacturer, Beverston Engineering, is boosting manufacturing capabilities with the development of a new, innovative…

Meet the Team Q and A: Michael Schraps

Name: Michael Schraps Company and role: Virtual Engineering Centre (University of Liverpool) LCR 4.0 Programme…