Hayes and Finch

Hayes and Finch are a traditional manufacturing company based in Aintree, supplying churches across the UK with an array of products including a wide range of candles, statues, furniture and furnishings including banners, confirmation cards, candle holders and collection baskets.

Challenge

Hayes and Finch met the LCR4 START team at a virtual event during a COVID-19 lockdown and reached out to the Virtual Engineering Centre to discuss the potential of adopting digital technologies to improve their productivity levels, in particular, within the production lines.

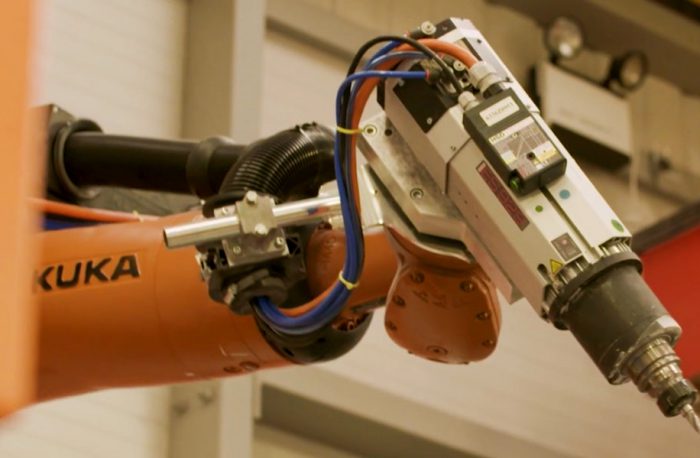

The company had recently purchased components to create and deploy four autonomous robotic arms which would be used within the production line for adding wicks to a selection of popular candles, which is currently done by hand.

Solution

The Virtual Engineering Centre worked with Hayes and Finch to assess the automation challenge, plan the development of the robotic arms, and implement a proof of concept using a single unit.

Successful use of these robotic arms within the production line will result in five thousand candles a day being finished and packaged to a high standard, whilst the operational staff can continue with other jobs and tasks, freeing their time and increasing productivity. The use of these robotic arms also ensures that all business functions remain in-house and current staff are trained to use such equipment.

The implementation of robotic arms not only increases the automation of the production line, but these devices can collect valuable business data, allowing business owners and decision makers to see the numbers of items being produced which enable Hayes and Finch to update their website and recorded stock numbers more efficiently, offering clients an improved service.

Impact

The robotic automation is currently under trial implementation, supported by VEC engineers. The company are also exploring how they can further digitise their testing and recording methods to improve the data they collect and the ease of doing so.

In addition to this Hayes and Finch would like to explore 5G technology for live streaming services to improve their customer offering as well as introducing digital collection plates. Although spurred by COVID19 such technology has the potential to provide an ongoing benefit to both places of worship and their congregants, especially those who may have difficulty attending in-person services.

The Virtual Engineering Centre are planning to investigate 5G options for Hayes and Finch and will support in setting up and testing this technology, ensuring the service selected is best suited to their company needs.

Download the case study here.

Hayes & Finch is a long-established business, and we use many skilled craftspeople to make our products. To compete, we need to evolve our manufacturing processes and make best use of the skills and resources in the business.

Will Hawkins, Sales & Marketing Director for Hayes and Finch

Working with the Virtual Engineering Centre, we realised that we could automate certain candle making processes which are tedious for our staff to do, but are important stages of candle production.

The VEC team were quick to understand our challenge and to develop a solution. We’re confident we will be able to free up hours of repetitive work for our staff and redeploy them on more skilled work.