The 6 steps your business needs for digital transformation

Digital is undoubtedly a hot topic capturing the attention of all engineering stakeholders and, while digital technologies can deliver results by cutting costs, identifying efficiencies and boosting productivity, the technologies themselves are only tools. Digital transformation is about much more than implementing those technologies and without a strategy in place, digital tools will not deliver the business transformation you are looking for.

The statistics show that up to 70% of digital transformation projects fail, even among multinationals whose scale of ambition and innovation is backed up by significant financial and skills input.

So, how can engineering businesses embrace digital without leaving themselves open to expensive failure?

While advanced modelling, simulation, virtual reality and the like can bring huge operational and commercial gains when applied astutely, the real driver for improved business performance is through the creation of digital strategies, business plans and roadmaps to develop, deliver and sustain a change project.

Companies which reap the benefits of Industry 4.0 are those whose executives have a clear future vision for their business, and the skills and authority to guide them from inception to implementation and beyond. They recognise that digitalisation is not a giant leap, but a ‘small steps’ process with a firm focus on the long-term.

Step One: Analysis

Before making any investment in hardware or software, engineering businesses should first analyse all functions within their business, taking into account the data and digital skills and tools they already have to work with. A SWOT analysis of business functions will establish where a digital approach, rather than a doing what we currently do digitally, could deliver enhanced performance, and future drivers for business, such as environmental sustainability, should also be considered.

Don’t try and make the digital solution fit the problem. First start by identifying operational changes that will improve performance, then move on to defining digital use cases that will enable those operational changes.

Step Two: Get Buy-in

True digital transformation is not a passive process. It requires engagement and support from top to bottom. But, change can create workforce uncertainty and there is an understandable, if perhaps misinformed, fear that digitalisation leads to job losses. Securing the support of your workforce is therefore crucial to any digital change project, and a well-designed and delivered strategy can support this.

Communication is key to securing the buy-in of your team. Tell them what you’re trying to achieve and be open about the roadmap you want to follow to get there. Try to build a digital culture to enable employees to embrace new technologies and invest in training to allow your team to feel a sense of ownership over that technology.

Step Three: Build a team

Digital technologies have the potential to disrupt business performance across all functions, as well as fostering increased commercial value for the company as a whole. An implementation team should therefore take into account all business functions.

Step Four: Be Flexible and Agile

The benefits of a holistic, well executed and dynamic digital strategy, which is not fixed in traditional static planning cycles, should both reap immediate results and set the agenda for continued innovation and growth in response to evolving technologies, business markets and customer demand.

Concentrating on business processes must not stop after the first wave of use cases. Additional opportunities for improvement should -and will – continue to emerge and you need to tweak and adapt your strategy as you go.

Step Five: Think Bigger

Successful digital transformation is not the preserve of big engineering firms. SMEs are generally agile in nature and this characteristic can enable them to adopt new digital tools and techniques much more quickly than larger organisations. A growing number of SMEs have seen the benefit of incorporating smart technologies to generate valuable real-time data and are using this information to help them make better decisions to grow their business.

Step Six: Collaborate

Think you don’t have the skills? University based digital impact centres offer a wealth of expertise, unbiased advice and practical support. For example, the Virtual Engineering Centre (VEC), which is part of the University of Liverpool, and its regional partners recently launched the LCR4 START initiative, (ERDF funded) offering targeted support to Liverpool City Region SMEs, to deploy digital technologies to achieve business gains, growth and savings.

For more information, please visit: www.lcr4.uk

The Made Smarter Review estimates that UK industry could achieve a 25% increase in productivity through digital adoption by 2025. The chance to capitalise on opportunities to embed operational efficiencies, accelerate speed to market for products and services, and enhance competitiveness and profitability, is one that should not be missed for want of a viable and sustainable strategy.

Explore more

Women in LCR 4.0 Cluster Group

Identifying and Promoting the Opportunities of 4th Industrial Revolution for Women within Liverpool City Region.…

Robots are taking over Liverpool’s jobs – here’s why it’s not all bad news

LCR 4.0 featured in an article in the Liverpool Echo discussing the benefits of robotics…

Podcasts

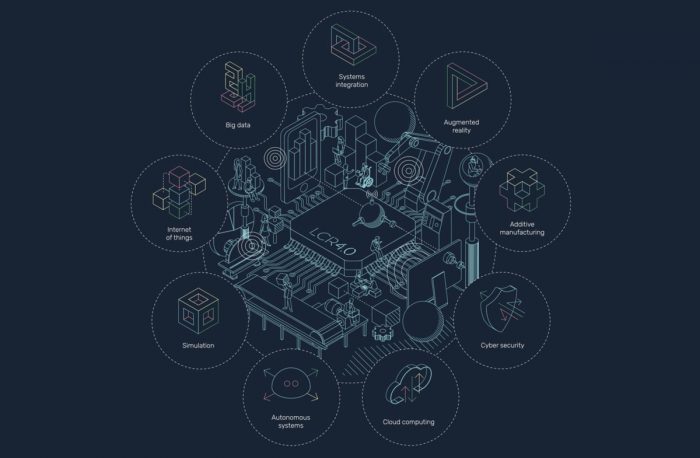

We have a number of podcasts which dive into industry further, discussing the 9 pillars…