Feedwater

Feedwater is a manufacturer and supplier of water treatment chemicals equipment and specialist services for industrial and commercial water systems. They work to keep commercial customers safe and industrial plants running, in line with their moto “keep them safe, keep them legal and keep them going.”

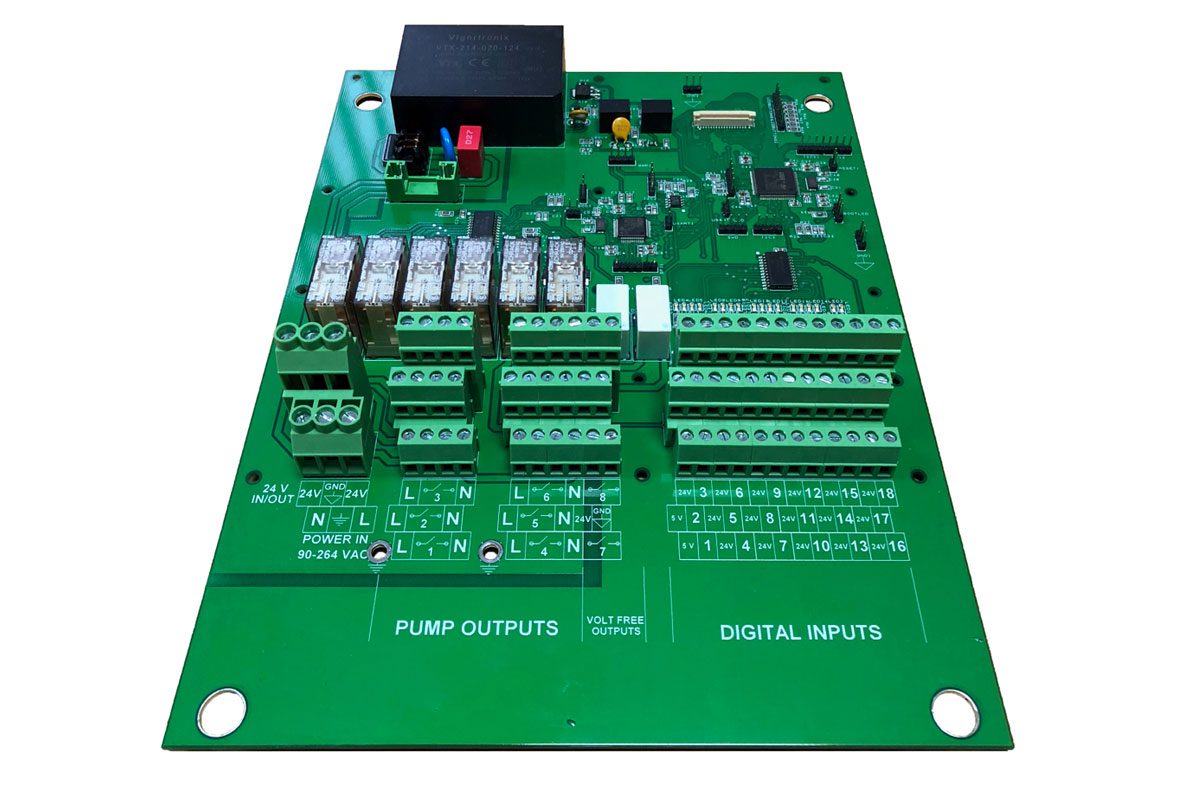

The Feedwater team were seeking help in the development of a new water treat dosage and control system.

Approaching LCR 4.0

Feedwater were first introduced to LCR 4.0 at a networking event. Impressed by what assistance could be offered through the programme, they engaged with it in the hope of shortening the development time of their new system.

One of the main attractions to LCR 4.0 was the ability to access the state of the art facilities within delivery partner Sensor City.

Partner Support

Technical support was provided for the electronics design for the system’s specified conductivity probe. Sensor City created a proposal for this work and then undertook testing of the peak detector circuit.

Access to the equipment at Sensor City allowed the LCR 4.0 team to remove and replace damaged chips on the prototype board and replace them with a new device.

Results

Through the work undertaken by the LCR 4.0 team, Sensor City has built a peak detector circuit to analyse the signal from the sensor and will design a conductivity module, which Feedwater plan to use in their new system. This will reduce development time by up to six months and ensure that the design is optimised before further prototypes are built.

Additionally, using the state-of-the-art testing and manufacturing equipment at Sensor City has allowed Feedwater to avoid outsourcing this work to expensive suppliers.

Working to the Future

Sensor City now plans to work with Feedwater to develop a filter, to make better sense of the signal from the sensor and design a complete conductivity module.

Feedwater’s end goal is to create their own standard system controller, rather than having to rely on a third-party controller, which is not compatible across all systems.

The facilities and expertise available at Sensor City have been really useful to us. I would definitely recommend other SMEs get involved with the LCR 4.0 project to take advantage of the support available.

Gregorio Navidad Vidal, Design & Development Engineer, Feedwater